Plate glass

Contents |

[edit] Introduction

Glass is a material made from liquid sand. It is an amorphous (non-crystalline) solid that displays a glass transition near its melting point which is around 1,700°C (3,090°F). This means that materials transform from a hard and brittle state into a molten state, or vice versa depending on whether the glass transition temperature is the melting or solidifying point. An amorphous solid has some of the crystalline order of a solid and some of the random molecular structure of a liquid.

There are many types of glass, each with different chemical and physical properties dependent upon their application.

For more information see: Glass.

[edit] History of plate glass

Plate glass is a type of glass that was first produced in plane form. The earliest successful version of plate glass was manufactured in France in the 17th century. It was an improvement over the cylinder glass or broad glass method, which required the glass maker to swing a bubble of molten glass back and forth whilst blowing, producing an elongated balloon that could be formed into the shape of a cylinder and then flattened into a sheet.

For more information, see Cylinder glass

The advance plate glass process was introduced by Louis Lucas de Nehou and Abraham Thevart. It involved casting the molten material onto a metal table and then grinding and polishing the glass by hand.

For more information, see Cast plate

This technique was automated in the 1800s when a steam engine took over the grinding and polishing process. The process improved again in the early 1900s, when machines were designed to incorporate methods including the Fourcault process, the Bicheroux process and others. Using these methods, plate glass could be manufactured in various weights and thicknesses. It was colourless and had good transparency, which is why it was once commonly used for large picture windows and glass doors.

[edit] Imperfections and distortions

While it was produced with a smooth finish, plate glass was not always entirely flat or parallel. This sometimes produced a slight distortion effect. Once float glass was introduced in the 1950s, plate glass became less popular.

Float glass created large, thin, flat panels from molten glass that were then floated onto a pool of molten metal such as tin. This process produced a very smooth sheet of glass with a highly consistent thickness.

For more information see: Float glass.

[edit] Related articles on Designing Buildings Wiki

Featured articles and news

CLC and BSR process map for HRB approvals

One of the initial outputs of their weekly BSR meetings.

Building Safety Levy technical consultation response

Details of the planned levy now due in 2026.

Great British Energy install solar on school and NHS sites

200 schools and 200 NHS sites to get solar systems, as first project of the newly formed government initiative.

600 million for 60,000 more skilled construction workers

Announced by Treasury ahead of the Spring Statement.

The restoration of the novelist’s birthplace in Eastwood.

Life Critical Fire Safety External Wall System LCFS EWS

Breaking down what is meant by this now often used term.

PAC report on the Remediation of Dangerous Cladding

Recommendations on workforce, transparency, support, insurance, funding, fraud and mismanagement.

New towns, expanded settlements and housing delivery

Modular inquiry asks if new towns and expanded settlements are an effective means of delivering housing.

Building Engineering Business Survey Q1 2025

Survey shows growth remains flat as skill shortages and volatile pricing persist.

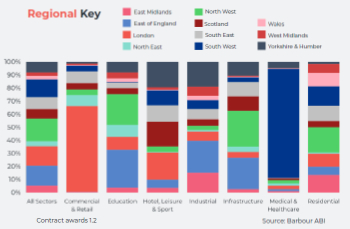

Construction contract awards remain buoyant

Infrastructure up but residential struggles.

Home builders call for suspension of Building Safety Levy

HBF with over 100 home builders write to the Chancellor.

CIOB Apprentice of the Year 2024/2025

CIOB names James Monk a quantity surveyor from Cambridge as the winner.

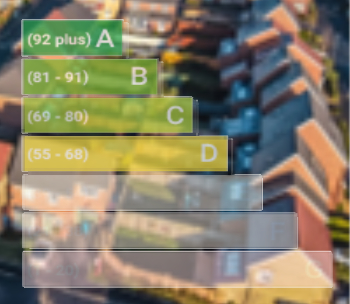

Warm Homes Plan and existing energy bill support policies

Breaking down what existing policies are and what they do.

Treasury responds to sector submission on Warm Homes

Trade associations call on Government to make good on manifesto pledge for the upgrading of 5 million homes.

A tour through Robotic Installation Systems for Elevators, Innovation Labs, MetaCore and PORT tech.

A dynamic brand built for impact stitched into BSRIA’s building fabric.

BS 9991:2024 and the recently published CLC advisory note

Fire safety in the design, management and use of residential buildings. Code of practice.